Drop-in seat, in foam – Part 1

February 12, 2020

This is the first part of a series of instructions on reupholstering a foam drop in seat. You will need to go to parts 2 and 3 for the full instructions.

TIP Use polythene to protect your surface and use a cloth soaked in white spirit to occasionally wipe your hands and the polythene surface. If your worktop is not the right height, try working on the floor.

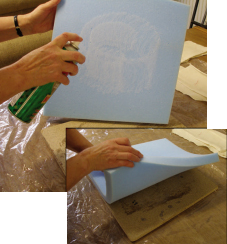

1. For this example we are using a board for the base of the seat but we could easily be using a webbed frame. Make sure the foam is cut about 10mm bigger than the board/frame. Spray the board and the foam with sufficient glue to hold it firm.

2. Tear pieces of calico or curtain lining about 13cm/5″ wide, in strips equal to the length of each side. The width of the strips can vary depending on the combined depth of the foam and base. My measurements are base on a total of 2″ of depth.

3. Lay one piece of the torn fabric about 3″ from the edge of the foam and spray glue on the fabric, as well as the foam that is showing between it and the edge. Enough to cover both well but not too heavy.

4. Bring the glued fabric back over the edge of the foam and smooth over the surface to ensure that it has adhered evenly.

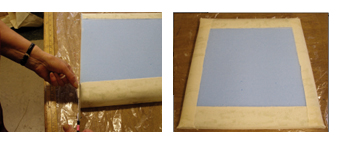

5. Turn the board or frame over with the strip of fabric facing away from you. Spray more glue on the edge of the board and foam.

6. Apply pressure with your body by leaning into the frame/board and press down with your hands creating yet further, even pressure with your fingers.

7. Without releasing the pressure, fold the fabric round, over the bottom of the frame/board.

8. Continue adding all the fabric strips and trim excess where necessary.

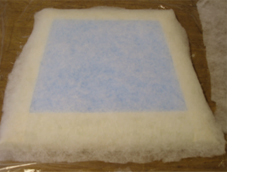

9. You should now have a seat with perfectly rounded edges. This method will stop the foam creeping back from the edge of the seat when it is used and protect the front edge from wear. The result is that the seat will look better, feel more comfortable and last longer.

10. Finally lay over a sheet of 4 oz polyester. It is now ready for the fabric.

In this project I have used a R300 foam (code: F11) in 1 1/4″ depth. If you are unsure how to calculate this, it is best to telephone us so that we can help you with your order.

SHARE