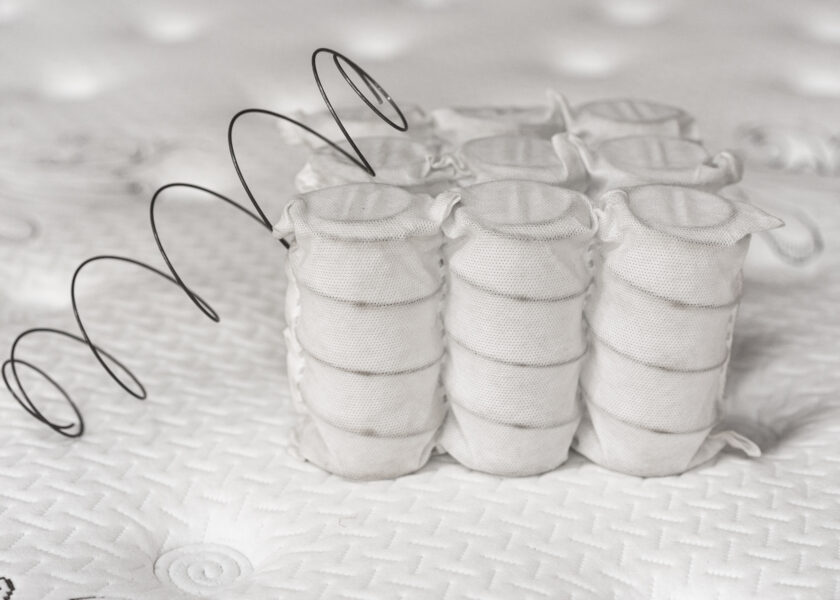

Restoring the Inside: When to Replace Webbing or Springs

The unseen structure of your upholstered furniture—its Springs and Webbing—is essential to comfort, durability, and longevity. Over time, these hidden supports can begin to sag, wear out, or fail entirely.…